Horizon 2020

Unisense A/S is part of the European Horizon 2020 framework. Horizon 2020 is the biggest EU Research and Innovation programme ever with nearly €80 billion of funding available over 7 years (2014 to 2020) – in addition to the private investment that this money will attract. It promises more breakthroughs, discoveries and world-firsts by taking great ideas from the lab to the market.” Horizon 2020.

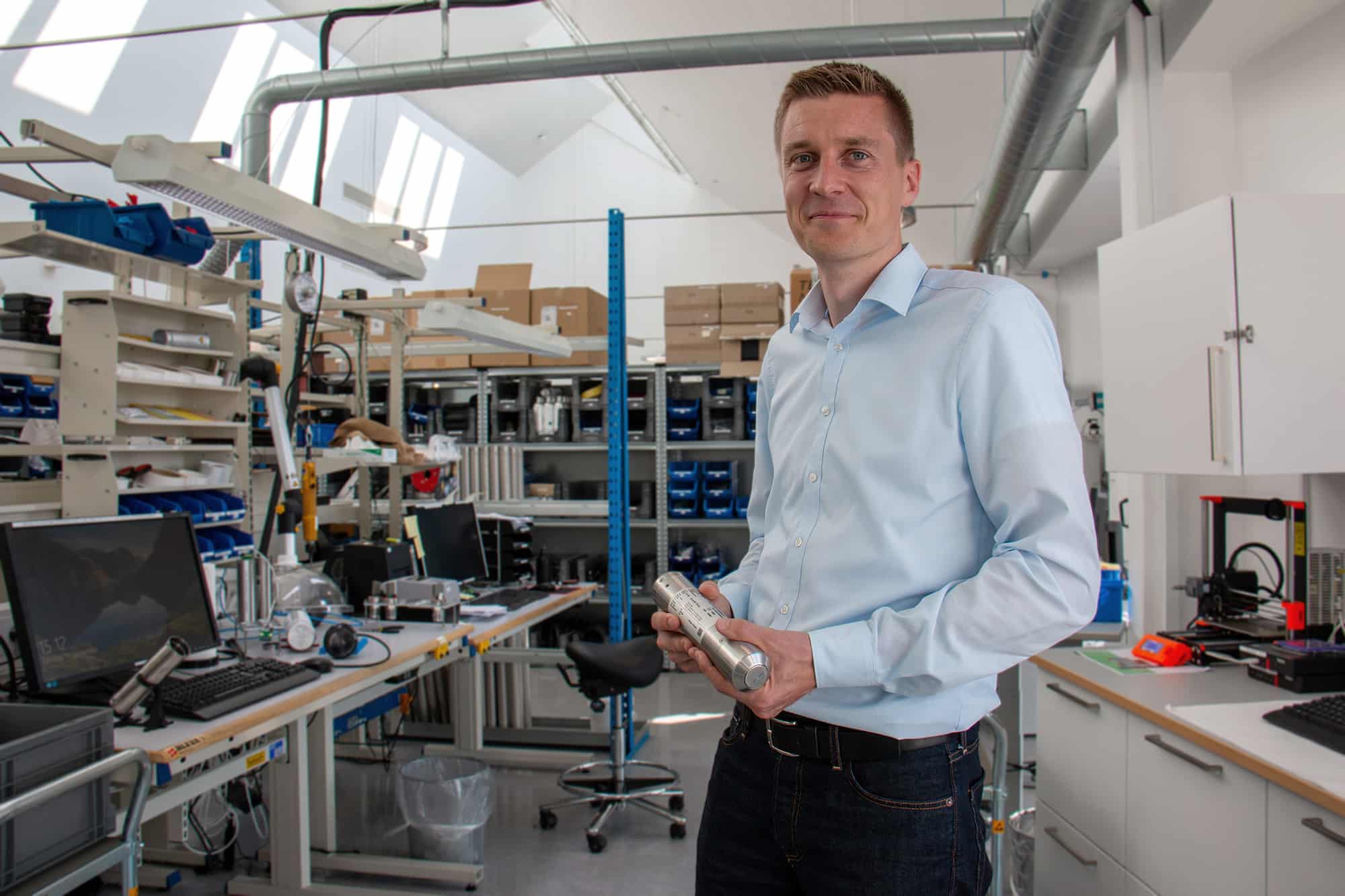

Horizon 2020 SME programme has granted funds for Unisense A/S to refine the performance of an Industrial Micro Electrochemical Cell sensor – iMEC.

Annually, the wastewater industry spends 88.4% of its budget in asset management – more specifically repairing and replacing sewer network, pipes, pumps, motors, etc. Those are recurrently the result of H2S formation in the sewage, which leads to corrosion and collapse of sewer systems, pumps and other equipment as it is highly toxic and flammable. It additionally causes odour nuisances and health issues for workers and population living nearby.

Unisense has developed a cost-effective and robust sensor for H2S monitoring in the liquid phase (the first of its kind). The iMEC sensor technology benefits from a long lifespan and an extremely high uniformity, enabling factory calibration and thus ready for scaling and associated mass-production. The sensor can be used with different objectives under either a reactive/day-to-day approach or under a more preventive HPAM strategy. The benefits of adopting iMEC sensors are a real-time accurate picture of H2S occurrence in the wastewater system, allowing the identification of most problematic spots and the installation of automatic chemical dosing systems. In an average size wastewater utility, the sensor can save up to €150 000 in chemical expenses, while the savings resulting from increasing asset lifetime and implementing an effective HPAM through sensor installation can lead to 15 – 40% savings in asset management, representing €0.5M – €1.3M for an average sized wastewater treatment plant.

The goal of the Horizon 2020 iMEC project is to overcome prominent barriers (e.g. technology risk perception, lack of knowledge regarding iMEC sensors benefits, certifications) that may hinder the sensor’s market uptake. Furthermore, the aim is to mature the technology and clearly demonstrate its benefits to the end-users, through in-situ, large demonstrations and product certification.

The major components of the iMEC project are:

- Further optimization of iMEC sensor design for sewer system applications.

- Full-scale testing and demonstration of a large number of iMEC sensors in operational environments, i.e. large city sewer systems to gather significant evidence of iMEC sensor functionality and benefits and obtain reference cases to use for marketing purposes.

- Refined product specifications as well as important certifications and compliance with standards such as ATEX and UL/ULC standards.

- Increased market awareness of iMEC and a refined value chain and business plan.