Get superior H2S data

The SulfiLoggerTM probe is ideal for many hydrogen sulphide monitoring applications in industries such as:

Measure H2S the easy way

Applications

The SulfiLoggerTM sensor’s reliable insights empower you to make smarter decisions. Among other applications, the sensor is ideal for these purposes:

Sensor specifications

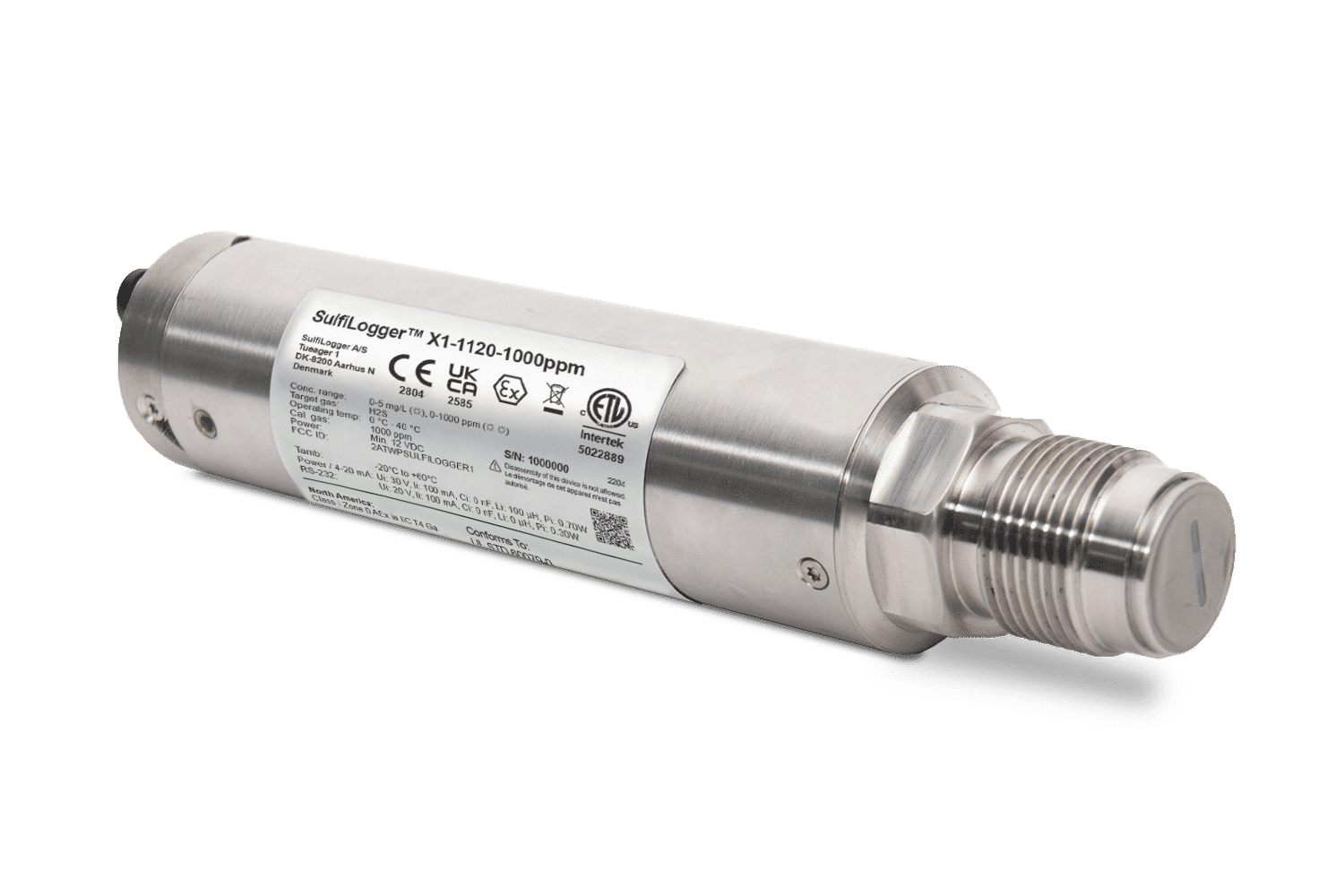

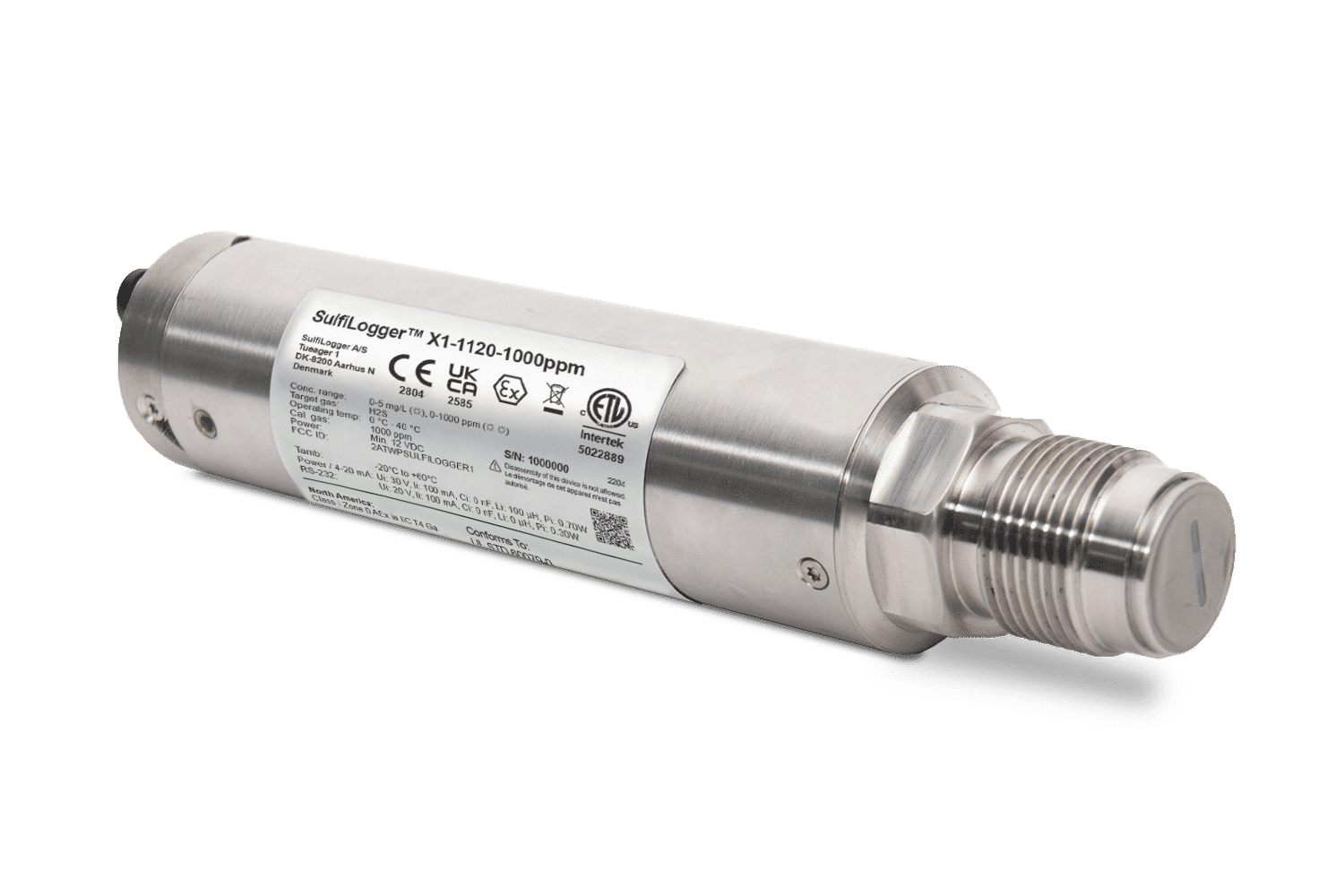

The SulfiLoggerTM H2S sensor measures the partial pressure of H2S.

It uses a novel and patent-pending microelectrochemical sensor technology that is robust even in challenging environments.

| Analyzer models | |

|---|---|

SulfiLoggerTM S1/X1-1020 SulfiLoggerTM S1/X1-1020 |

|

| Measurement media | Wastewater (mg/L) Air (ppm) |

| Measurement range | Low range 0-0.5 mg/L 0-100 ppm |

| Normal range 0-5 mg/L 0-1000 ppm |

|

| Custom range Custom measurement ranges upon request |

|

| Max pressure | 3 barg (44 psig) |

| Operating temperature range | 0 °C to +40 °C (32 °F to +104 °F) |

| Front design | Passive anti-fouling flush front for sensor submersion |

| Material | Stainless Steel EN 1.4404 (316L) |

| Price | |

SulfiLoggerTM S1/X1-1120 SulfiLoggerTM S1/X1-1120 |

|

| Measurement media | Pressurized wastewater (mg/L) Biogas (ppm) |

| Measurement range | Low range 0-0.5 mg/L 0-100 ppm |

| Normal range 0-5 mg/L 0-1000 ppm |

|

| Custom range Custom measurement ranges upon request |

|

| Max pressure | 3 barg (44 psig) |

| Operating temperature range | 0 °C to +40 °C (32 °F to +104 °F) |

| Front design | Threaded G 1″ (ISO 228-1, BSPP) |

| Material | Stainless Steel EN 1.4404 (316L) |

| Price | |

SulfiLoggerTM X1-1220 SulfiLoggerTM X1-1220 |

|

| Measurement media | Pressurized process water (mg/L) Natural gas (ppm) |

| Measurement range | Low range 0-0.5 mg/L 0-100 ppm |

| Normal range 0-5 mg/L 0-1000 ppm |

|

| Custom range Custom measurement ranges upon request |

|

| Max pressure | 3 barg (44 psig) Custom pressure rating upon request |

| Operating temperature range | 0 °C to +60 °C (32 °F to +140 °F) |

| Front design | Threaded G 1″ (ISO 228-1, BSPP) |

| Material | Surface treated stainless steel for improved corrosion resistance EN 1.4404 (316L) |

| Price | |

| H2S sensor models | |||

|---|---|---|---|

SulfiLoggerTM S1/X1-1020 SulfiLoggerTM S1/X1-1020 |

SulfiLoggerTM S1/X1-1120 SulfiLoggerTM S1/X1-1120 |

SulfiLoggerTM X1-1220 SulfiLoggerTM X1-1220 |

|

| Measurement media | Wastewater (mg/L) Air (ppm) |

Pressurized wastewater (mg/L) Biogas (ppm) |

Pressurized process water (mg/L) Natural gas (ppm) |

| Measurement range | Low range 0-0,5 mg/L 0-100 ppm |

Low range 0-0,5 mg/L 0-100 ppm |

Low range 0-0,5 mg/L 0-100 ppm |

| Normal range 0-5 mg/L 0-1000 ppm |

Normal range 0-5 mg/L 0-1000 ppm |

Normal range 0-5 mg/L 0-1000 ppm |

|

| Custom range Custom measurement ranges upon request |

Custom range Custom measurement ranges upon request |

Custom range Custom measurement ranges upon request |

|

| Max pressure | 3 barg (44 psig) | 3 barg (44 psig) | 3 barg (44 psig) Custom pressure rating upon request |

| Operating temperature range | 0 °C to +40 °C (32 °F to +104 °F) |

0 °C to +40 °C (32 °F to +104 °F) |

0 °C to +60 °C (32 °F to +140 °F) |

| Front design | Passive anti-fouling flush front for sensor submersion | Threaded G 1″ (ISO 228-1, BSPP) |

Threaded G 1″ (ISO 228-1, BSPP) |

| Material | Stainless Steel EN 1.4404 (316L) |

Stainless Steel EN 1.4404 (316L) |

Surface treated stainless steel for improved corrosion resistance EN 1.4404 (316L) |

| Price | |||

| Technical specifications | |

|---|---|

| Accuracy | +/- 5% of reading |

| Detection limit | 1% of full range |

| Response time | <25 seconds |

| Operating humidity range | 0-100% |

| Max water depth | 10 metres |

| Storage temperature range | 0 °C to +40 °C

(32 °F to +104 °F) |

| Design temperature range | -20 °C to +60 °C

(-4 °F to +140 °F) |

| Power input options | 4-20 mA loop power

DC power (12-28 VDC) Batteries* |

| Data output options | 4-20 mA analogue signal

RS-232 digital signal Cloud data* |

* With the PowerCom Box only.

| Mechanical & other specifications | |

|---|---|

| Length | 240 mm (9.4 in) |

| Diameter | 48.3 mm (1.9 in) |

| Weight | 0.85 kg (1.9 lb) |

| Warranty | 1 year** |

| Chemical interferences specifications | |

** When used in accordance with the Installation Manual.

| Certification | |

|---|---|

S1-series:   |

|

X1-series:

|

*** SulfiLogger™ X1 only. Certificates are available on sulfilogger.com/support.

Want to know more?

Would you like to know more about the SulfiLoggerTM sensor?

Send us an inquiry and we will get back to you.