A framework for H2S control strategies

Are your hydrogen sulfide control activities aligned with your objectives? Learn how to select the appropriate control strategy for specific applications.

Introduction

In this insights story, we present a basic framework for selecting the optimal H2S control strategy. This framework emphasizes why reliable hydrogen sulfide data is a key variable for deciding and optimizing control strategies.

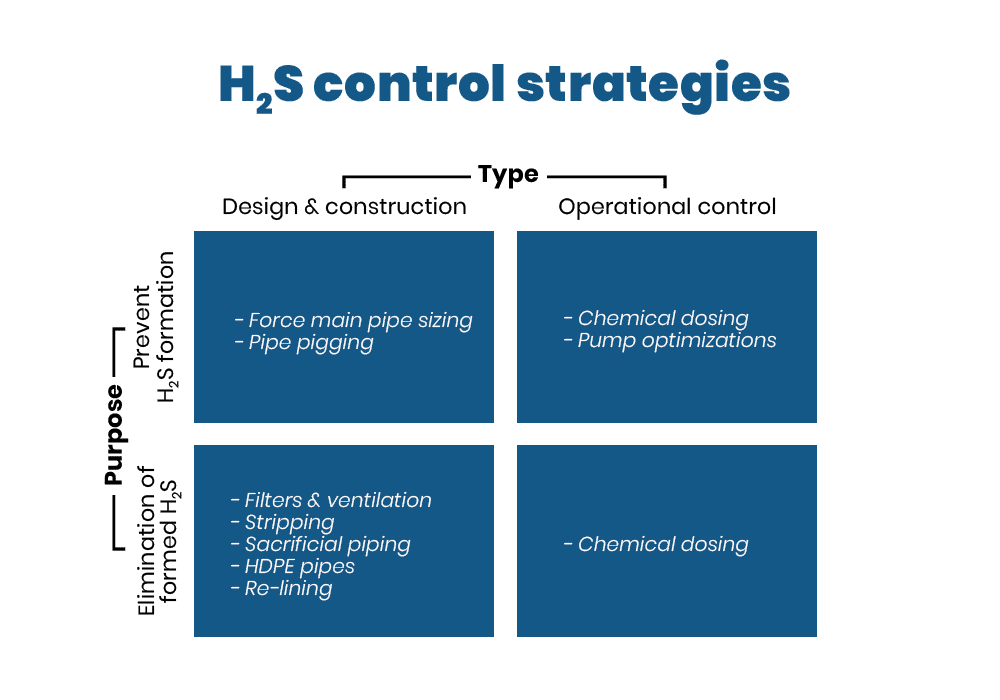

For this basic framework, we divide the different control strategies into four quadrants based on what you want to achieve (the purpose) and how you want to do it (the type of action). In this framework, the control strategies seek to either prevent or eliminate hydrogen sulfide formation using either construction projects or operational control optimizations.

H2S control framework

The basic framework is presented in this figure (click to enlarge):

Design and construction strategies

The design and construction strategies are primarily CapEx (Capital Expenditure) focused activities involving various construction projects.

Here, reliable hydrogen sulfide data is a critical data input for deciding what to do, where to do it, and to evaluate if the activity performs as expected. This can be achieved by measuring the sulfide load on critical network hotspots both before and after construction projects.

Design and construction strategies to limit hydrogen sulfide formation include selecting the proper pipe dimensions for force mains and establishing pipe-pigging setups. To eliminate already formed H2S, design and construction strategies focus on preventing stagnant water conditions or using corrosion-resistant materials.

Operational control strategies

The operational control strategies are more OpEx (Operational Expenditure) focused activities. These strategies can include chemical dosing operations to either prevent/inhibit hydrogen sulfide formation (e.g., by dosing nitrate or air) or to eliminate/precipitate the hydrogen sulfide once it has been formed (e.g., by dosing iron salts).

For the operational control strategies, reliable H2S data is a useful input for optimizing dosing stations by matching dosing rates to actual requirements and thereby preventing excessive dosing. This optimization in turn reduces OpEx and improves environmental compliance.

Summary

Regardless of your choice of H2S control strategy, reliable hydrogen sulfide data is a key input that enables fact-based decision-making for design activities and ongoing optimizations of existing operational control strategies.

Would you like to know more about how you can use data to make smarter decisions? Catch us in the live chat (click the chat icon in the lower right corner) and let’s discuss your application or hydrogen sulfide-related challenge.