Case study

New sensor provides better H2S insights in sewer networks

This case study shows that a new sensor technology provides better insights into how hydrogen sulfide impacts sewer networks by continuously measuring H2S directly in or just above untreated wastewater. This new approach to H2S monitoring delivers true and reliable data that allow wastewater utilities to manage and optimize H2S mitigation activities on a fully informed basis.

Background

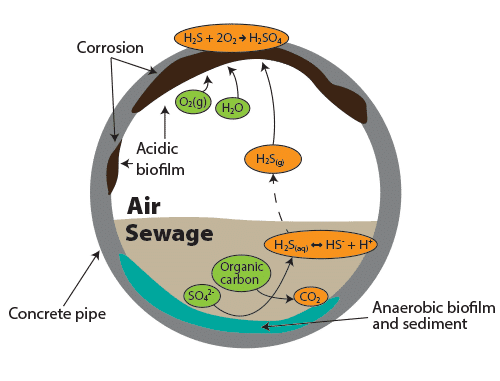

The toxic, foul-smelling, and highly corrosive gas hydrogen sulfide (H2S) poses a major challenge to wastewater utilities.

H2S is formed when wastewater is pumped through force mains, and the H2S induced odor and corrosion issues are commonly found in hotspots right after the discharge into the gravitational sewer system. Here, part of the dissolved H2S is released into the air, while another part remains in the sewage where it is transported further downstream in the network if left untreated.

Challenge

Wastewater utilities typically use gas loggers to monitor H2S concentration changes in the diluted air below manhole covers. However, seeing as H2S is produced and transported in the wastewater and not in the air, wouldn’t it make more sense to measure it in the wastewater?

This case study thus investigates if continuous liquid-phase measurements can provide a better approach to H2S monitoring than gas-phase measurements and deliver better insights into how H2S impacts sewer hotspots.

Setup

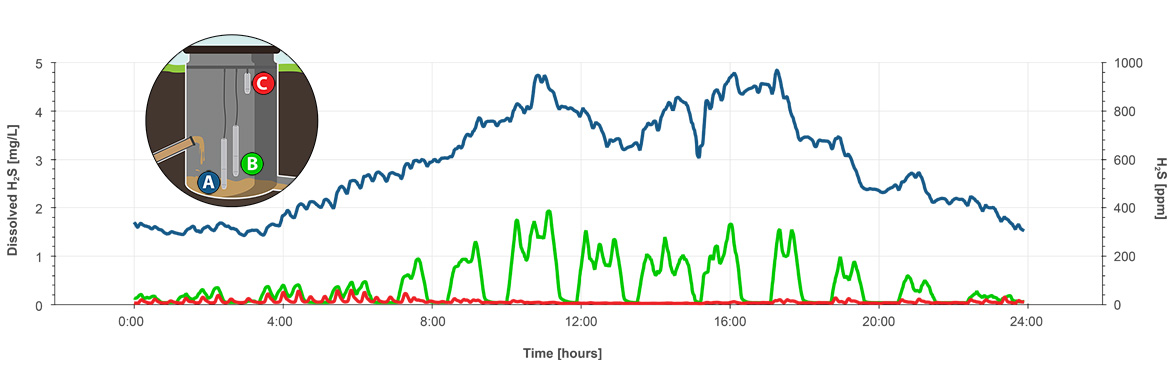

To analyze the benefits of measuring H2S directly in the wastewater, three SulfiLoggerTM H2S sensors were installed in the same 3-metre deep force main discharge well at a Danish wastewater utility. Capable of continuously measuring H2S in both gas and liquid phase, the SulfiLoggerTM sensors were installed in the raw wastewater (A), in the headspace just above the wastewater (B), and in the headspace just below the manhole cover (C).

Results

As seen on the graph, the liquid-phase measurements (A) provide a full overview of how H2S impacts the sewer hotspot. The gas-phase measurements in the air above the sewage (B) were correlated with the liquid-phase measurements, while the gas-phase measurements in the diluted air just below the manhole cover (C) were unable to uncover the severity of the H2S challenge. The major deviation in the gas-phase data suggests these measurements were heavily affected by factors such as turbulence, ventilation, and pumping rhythms.

A new approach to H2S management

The SulfiLogger™ sensor’s liquid-phase measurements reveal the true scope of a utility’s H2S challenge. This knowledge enables a data-driven approach to H2S management for greatly improved corrosion control, optimized chemical dosing, effective root cause analysis, and optimized planning of new infrastructure projects. Finally, the SulfiLoggerTM sensor’s unique ability to measure both in and above wastewater makes it a flexible tool suitable for odor detection campaigns as well.

Want to know more?

Do you want to hear more about the benefits of measuring H2S directly in wastewater?