The benefits of dosing chemicals for H2S mitigation end-of-pipe

Did you know there is another approach to chemical dosing than start-of-pipe dosing at the pumping station? This post explores the concept of end-of-pipe dosing and all the benefits this approach enables.

Introduction

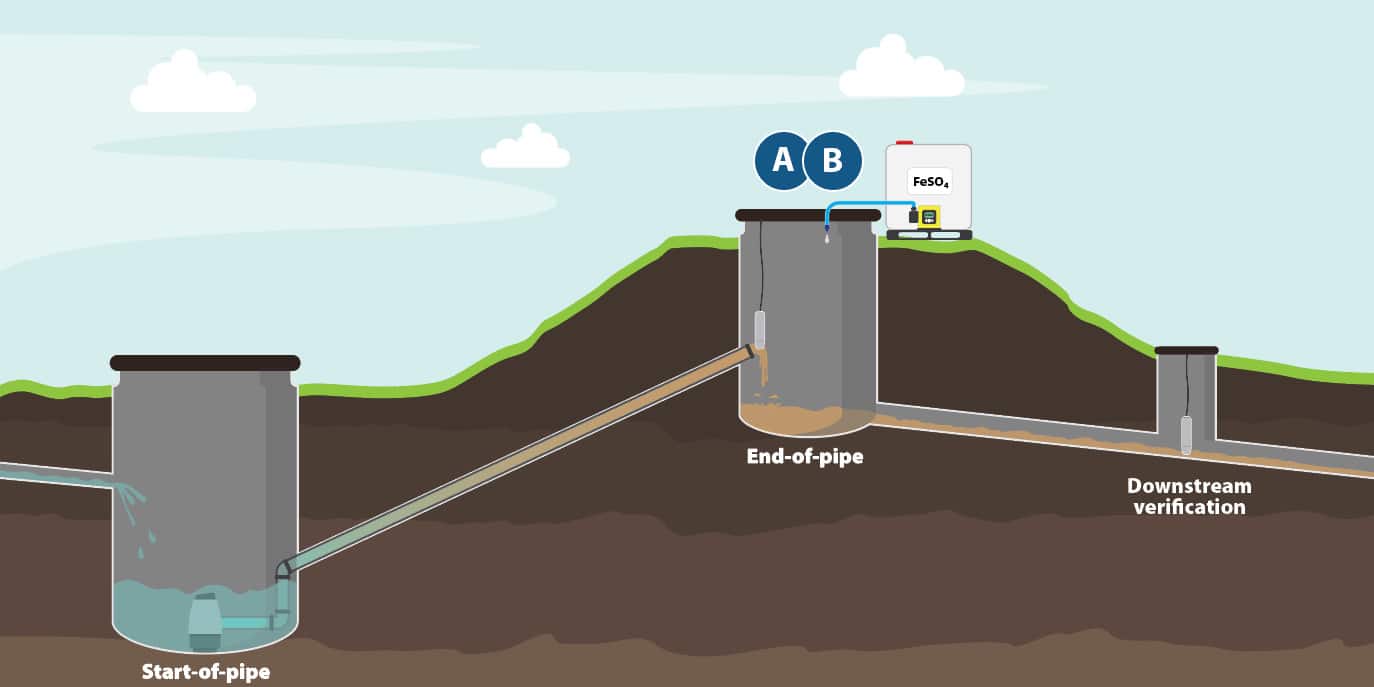

Utilities often add neutralization agents to sewage to prevent odor and corrosion problems. These chemicals are typically added at the pumping station, as this location supports SCADA and power integration and because it has the space required to house large chemical tanks. However, this location is unfortunately the most difficult place to achieve an efficient dosing of chemicals. And as an effect, chemicals are therefore often added excessively in a constant dose. In this insights story, we will explain why the optimal location to obtain a cost-effective and environmentally sustainable dosing of chemicals is at the end of the pressurized pipe – not at the start.

The shortcomings of dosing chemicals at the pumping station

There are two intertwining obstacles associated with dosing chemicals for H2S mitigation at the pumping station.

- H2S is a dynamic parameter that varies on a daily and seasonal scale as it is directly affected by changes in discharge patterns by residents and industries. On a daily scale, these variations in H2S may include “spikes”, i.e. short periods with very high H2S concentrations that cause odor and corrosion problems.

- There is a significant delay between the dosing and its effect. This delay is caused by the wastewater’s hydraulic retention time (HRT) – i.e. the time it takes for a wastewater package to move to the end of the pressurized pipe.

If a H2S spike is observed at the end of the pressurized pipe, it is difficult to instantaneously adjust the dosing rate accordingly. This is unfortunately the case, because changes made to the dosing impact a different package of wastewater and because the effect therefore materializes several hours later.

The benefits of end-of-pipe chemical dosing

There are several benefits to dosing chemicals end-of-pipe.

At the end of the pressurized pipe, all the beforementioned problems caused by the wastewater’s HRT no longer exists. Here, it is possible to dose fast-reacting chemicals instantaneously and directly proportional to the current H2S concentration in the wastewater. It is therefore possible to add chemicals only when needed and in the exact right quantity rather than in excess.

Another benefit relates to the layout of the sewer system. Some discharge wells act as the end-point for multiple rising mains, and using an end-of-pipe dosing strategy, it is thus possible to mitigate H2S issues from multiple pressurized sewer lines with a single chemical dosing station.

Final remarks

Although the end-of-pipe dosing may be difficult to establish at certain discharge wells due to space and connectivity constraints, it is nevertheless the ideal location to achieve an environmentally sustainable and cost-effective dosing of fast-reacting chemicals using dynamic, H2S sensor-controlled dosing.

Would you like to know more about the perspectives of dosing chemicals for H2S mitigation end-of-pipe? Then check out our this case study!

Case study

“Danish utility achieves 50% chemical savings using sensor-controlled dosing end-of-pipe”