The advantages of liquid-phase H2S measurements

Hydrogen sulfide (H2S) can be measured in many ways in wastewater systems. As such, there are no methods that are right or wrong. But it is important to keep in mind whether the chosen measurement approach provides the needed insights.

In this insights story, we examine the characteristics of the two primary methods for obtaining dynamic insights into the development of hydrogen sulfide in sewer systems and at wastewater treatment plants: gas phase and liquid phase measurements.

The challenge of gas-phase measurements

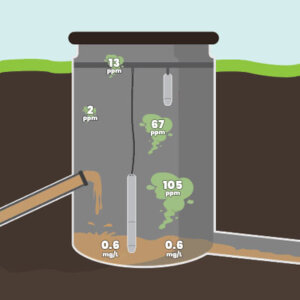

The sulfide concentration in the air is influenced by many factors including turbulence, ventilation, and the distance to the sewage. It is not unusual to see different sulfide concentrations in different positions in the same well.

Gas-phase measurements are the most common method for continuous measurements of hydrogen sulfide in wastewater systems. The gas loggers measure the degassed sulfide in the air under the manhole cover, and they typically require extended dry-out time in between measurement campaigns to get the best result. They are an excellent solution if the primary purpose is to determine if there are hydrogen sulfide-related odor nuisances at or near a measurement point.

Unfortunately, gas-phase measurements are not perfect, and the main challenge and shortcoming of this measurement approach are that the measurements are affected by local factors including turbulence, ventilation, and pumping rhythms. This shortcoming limits the gas loggers’ range of application.

The benefits of liquid-phase measurements

Liquid phase measurements are a new approach to continuous measurements of hydrogen sulfide in wastewater systems. The primary benefit of this approach is that because the sensors measure the dissolved sulfide directly in the sewage, the measurements are unaffected by the local conditions at the measurement site (turbulence, ventilation, and pumping rhythms). And therefore, the measurements provide reliable insights into the full, downstream sulfide potential of an entire sewer line. Liquid-phase measurements are thus excellent both as an input for the planning and redesigning of sewer lines, but also for advanced H2S mitigation applications including sensor-controlled chemical dosing or aeration.

Conclusion

In short, gas-phase measurements are excellent at detecting odors but not suitable for other H2S control applications. Liquid-phase measurements provide superior insights into the full downstream sulfide potential and are suitable for a wide range of H2S control applications including chemical dosing control.

| Purpose | Gas-phase measurement | Liquid-phase measurement |

|---|---|---|

| Local odor documentation | ||

| Downstream odor risk assessment | ||

| H2S neutralization effect verification | ||

| Chemical dosing control | ||

| Detect source of problem | ||

| Verify if problem is new or old |