Troubleshooting

SulfiLogger™ sensor

- Check the power supply.

- If powered by the SulfiLogger™ PowerCom Box, disconnect external loop-power from the PowerCom Box.

- Inspect the cables.

- Exchange the cables if they appear damaged.

- If the sensor connectors appear damaged, contact SulfiLogger support.

Contact SulfiLogger support.

- Ensure the calibration cap is aligned correctly. Consult the installation manual for more information.

- Move the cap slightly in either direction to trigger the calibration mode to start.

- Contact SulfiLogger support if the issue persists.

- Wipe the front of the sensor with a soft, wet cloth to remove potential fouling.

- Check that the gas bottle has sufficient pressure (>5 bar), and the flow regulator is fully open during calibration.

- Check that you are using the correct concentration of calibration gas.

- Make sure to open the flow regulator immediately after the calibration cap has been attached to the sensor.

- Try recalibrating the sensor with the abovementioned tips in mind.

- If unsuccessful, contact SulfiLogger support.

- Ground the system.

- Ensure that cables are not exposed to electrical noise.

- Contact SulfiLogger support.

- If the H2S signal at 0% H2S is above 1% of the SulfiLogger sensor range, consult the manual and perform a baseline calibration.

Contact SulfiLogger support.

Contact SulfiLogger support

- Wipe the front of the SulfiLogger™ sensor with a soft, wet cloth to remove potential fouling.

- Calibrate the sensor.

- If the pressure in the system is different from atmospheric pressure, the SulfiLogger™ sensor’s signal can be corrected to reflect the actual ppm value (only relevant for ppm measurements). See more information on sulfilogger.com/support.

- If measuring in liquid and comparing to total sulfide measurements, the H2S gas reading by the sensor needs to be converted to total sulfide using the pH of the system.

- Consider if anything is interfering on the sensor signal. See more information on sulfilogger.com/support.

Consult the manual and ensure the sensor is powered correctly.

Ensure there is galvanic isolation between the two signals.

- Install the cable guard inside a fixated PVC pipe as described in the installation manual.

- Use Loctite 243 when fastening the screws on the cable guard.

SulfiLogger™ PowerCom Box & SulfiLogger™ WebData

- Verify that the SulfiLogger™ PowerCom Box’ LED is flashing.

- Ensure that the SulfiLogger™ PowerCom Box is powered correctly.

- When the SulfiLogger™ PowerCom Box is powered, it can take up to 15 minutes to connect. Ensure that sufficient time has passed before proceeding.

- Reset the SulfiLogger™ PowerCom Box by flipping the on-off switch to the ‘off’ position, remove the batteries, leave them out for 10 min, then insert the batteries in the same spot as before, and flip the switch back to ‘on’. If the SulfiLogger™ PowerCom Box is DC powered, disconnect the power for 10 min. without any batteries installed. If battery-powered, insert new batteries.

- Try moving the SulfiLogger™ PowerCom Box to an area with better connection. Consider adding an external antenna.

- Reconnect the SulfiLogger™ sensor cables. Ensure they are firmly tightened at the SulfiLogger™ sensor. Ensure the cables in the SulfiLogger™ PowerCom Box’ terminals are secure (pull to confirm).

- Check the cables for any sign of damage or wear. Exchange cables if damaged.

- If the SulfiLogger™ sensor connectors appear damaged, contact SulfiLogger support.

- Ensure the SulfiLogger™ sensor is connected and that the status LED is flashing.

- Ensure the SulfiLogger™ PowerCom Box is powered by batteries or DC power.

- Reset the SulfiLogger™ PowerCom Box by flipping the on-off switch to the ‘off’ position, remove the batteries, leave them out for 10 min, then insert the batteries in the same spot as before, and flip the switch back to ‘on’. If the SulfiLogger™ PowerCom Box is DC powered disconnect the power for 10 min.

- Change battery A/B. Always exchange batteries one at a time. Always insert new batteries.

- The SulfiLogger™ PowerCom Box needs battery power to transmit a battery status. It can take up to 24 hours for the battery status to update correctly.

Contact SulfiLogger support if the battery status does not match your expectations.

- Always exchange batteries one at a time. Always insert new batteries. The SulfiLogger™ PowerCom Box needs battery to be powered to transmit battery status. It can take up to 24 hours for the battery status to update correctly.

- When a battery is removed and a new battery is installed, the inserted battery will appear with a charge state of 100% independent of the actual charge state of the battery.

- Contact SulfiLogger support if the battery status does not match your expectations.

- Reset the SulfiLogger™ PowerCom Box by flipping the on-off switch to the ‘off’ position, remove the batteries, leave them out for 10 min, then insert the batteries in the same spot as before, and flip the switch back to ‘on’. If the SulfiLogger™ PowerCom Box is DC-powered, disconnect the power for 10 min without any batteries installed. Allow time for the SulfiLogger PowerCom Box to connect.

- If battery-powered, insert new batteries. Allow time for the PowerCom box to connect.

- Contact SulfiLogger support if the issue persists.

- Check that the status LED on both the SulfiLogger™ sensor and on the SulfiLogger™ PowerCom box are flashing. Check that the SulfiLogger™ PowerCom Box is transmitting data to SulfiLogger™ WebData.

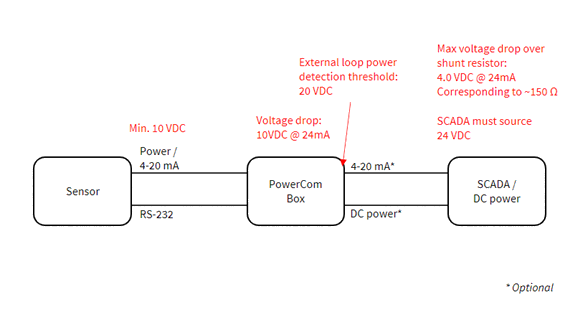

- Check that the 4-20 mA cable is correctly connected according to the manual. The SulfiLogger™ PowerCom Box still needs to be powered by either batteries or DC. The SCADA system needs to source 24 VDC to the 4-20 mA connection.

- The SulfiLogger™ sensor needs to be powered with minimum 10 VDC. The SulfiLogger™ PowerCom Box will turn off the 4-20 mA signal if the voltage input to the PowerCom box drops below 20 VDC.

- The resistor in the SCADA system can cause the voltage to drop below the threshold. The resistance must be less than 150 Ω.

- If the resistor in the SCADA system is not known, it can be tested in the following way.

- Place the SulfiLogger™ sensor in an environment free of H2S.

- Disconnect the external 4-20 mA connector from the SulfiLogger™ PowerCom Box.

- Measure the voltage from the SCADA system with a multimeter. It should be around 24 VDC.

- Connect the sensor directly to SCADA (bypassing the SulfiLogger™ PowerCom Box). The status LED on the sensor must flash green.

- Measure the voltage from the SCADA system again. The voltage difference to the previous measurement must be less than 600 mV. If not, the resistor will cause a voltage drop that turns off the 4-20 mA signal from the SulfiLogger™ PowerCom box.