Case study

Danish Biogas plant preparing for dynamic FeCl2 dosing

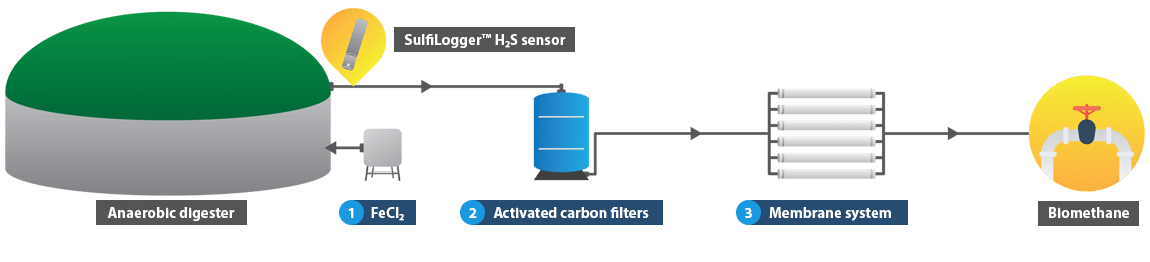

The operator of a Danish biogas plant is preparing to start dynamic FeCl2 dosing to cost-optimise the plant’s 3-stage desulphurisation process. Measuring in the wet and unprocessed biogas right after an anaerobic digester, a SulfiLoggerTM H2S sensor provides continuous H2S data, enabling the operator to adjust the injection rate of FeCl2 to match actual H2S levels in the next step of the project.

Background

A Danish biogas plant operator with an annual production of more than 5 million m³ of biomethane wants to optimise his running costs for desulphurisation.

The plant’s primary feedstock is chicken manure, hay and crops from nearby operations, and the sludge is used as fertilizer for the fields. Although only a couple of years old, the plant is already highly successful and therefore in the process of being upgraded to increase the production capacity even further.

Desulphurisation setup

The biogas is purified via a 3-stage desulphurisation process. In the first stage, the operator doses FeCl2 directly into each of the plant’s five anaerobic digesters. Following this, the gas enters activated carbon filters for further gas desulphurisation before a membrane system upgrades the gas to biomethane for the natural gas grid. The operator currently monitors the H2S levels in the process gas using a traditional multi gas analyser installed just before the activated carbon filters. The multi gas analyser provides spot measurements of conditioned gas at fixed intervals.

Purpose

Despite being a critical part of biogas operations, desulphurisation is an often-overlooked optimisation parameter due to the difficulties involved with acquiring accurate and reliable H2S measurements in biogas processing.

With this project, the operator wants to dynamically adjust the FeCl2 injection rate to optimise his cost of chemicals while maintaining the optimal lifespan on costly activated carbon filters and protecting the delicate membrane system from corrosion induced by hydrogen sulphide spikes.

Solution

An inline SulfiLoggerTM H2S sensor was installed outdoors in a side-stream right after one of the five anaerobic digesters. The sensor measured directly in the wet and unconditioned biogas with temperature and pressure ratings well within the specifications of the sensor. The ATEX certified SulfiLoggerTM sensor provided continuous, online H2S data via a cloud solution. The sensor could also have been integrated into the company’s existing PLC/SCADA system using the sensor’s 4-20 mA output.

Results

The SulfiLoggerTM H2S sensor provided the plant operator with a complete overview of the real-time presence of hydrogen sulphide after the digester. Disregarding the fluctuations, the H2S levels in the gas coming out of the digester were generally quite low, suggesting the operator is dosing excessive quantities of FeCl2 for long periods of time.

Perspectives

Sample-based H2S analyzers do not provide an ideal input for dynamic chemical dosing in biogas, as they deliver a static snapshot rather than a full overview over time. By relying solely on sample-based measurements for adjusting chemical injection rates, biogas operators risk dosing either excessive quantities to match peak loads of H2S or insufficient amounts minimising the lifespan of assets. Using the novel SulfiLoggerTM H2S sensor, biogas operators can optimise H2S mitigative actions for lower running costs and improved asset management.

Stay tuned for more updates in the next stage of the project, as the operator starts adjusting the injection rate to match actual H2S levels.

H2S readings from the SulfiLoggerTM H2S sensor measuring right after an anaerobic digester. The top graph shows the full 5 day data set, while the bottom graph highlights a period of 2½ hours at the end of the second day (marked in red).

Both graphs show frequent process-induced fluctuations in the H2S levels in the gas coming out of the digester. The half-hourly fluctuations shown in the bottom graph are caused by the mixer turning on and off at that rate.