3 strategies for smart H2S dosing control

Do you want to optimize the dosing of chemicals for hydrogen sulfide control?

In this insights story, we provide 3 strategies you can use to get started dosing chemicals the smart way.

Introduction

Wastewater utilities around the world dose chemicals to mitigate odor and corrosion problems in sewer systems. Unfortunately, the chemicals are often added in excess because it is difficult for the utilities to measure the effectiveness and thus find the appropriate dosing strategy.

There are many possible solutions to the excessive dosage problem. One solution is H2S sensor-controlled dosing, where real sensor data is used to find the optimal dosing rate. Sensor-controlled dosing may sound complicated, but it does not have to be difficult to get started with this approach.

In this insight story, we present 3 different strategies for how you can get started dosing chemicals the smart way.

For all strategies, the key data input is continuous sensor data from a liquid-phase H2S sensor that measures the effectiveness of a chemical dosing station. This data is then used in various ways as a control input for the dosing. To keep the strategies as simple as possible, we do not distinguish between specific types of chemicals – e.g., ferrous sulfate or nitrate-based chemicals. You are welcome to view our recorded webinars if you would like a more in-depth take on smart chemical dosing strategies.

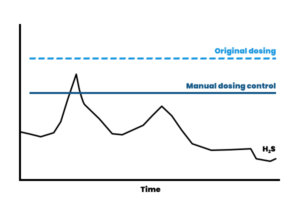

Manual dosing control

Manual dosing control: A shift in a constant dosing rate.

The easiest dosing strategy to get started with is manual dosing control. Here we use effect measurements to manually increase or decrease a constant dosing rate, after which we make a new assessment of the effect and perform further manual adjustments. This loop continues at a given frequency throughout the season to account for the effect of changing conditions. It is a simple control strategy that does not yield the same results as the more advanced strategies. But it is nonetheless a simple method to get started with smart dosing and achieve the easiest optimizations.

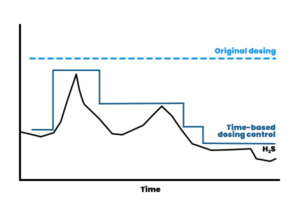

Time-based dosing control

Time-based dosing control: Rule-based dosing pattern.

In the time-based dosing control strategy, we expand on the manual dosing control strategy. The development of hydrogen sulfide typically follows daily patterns, and by setting up simple time-based rules for the dosing, we can achieve an even better effect.

With time-based dosing control, we increase the dosage in the periods where the hydrogen sulfide concentrations are the highest, while we conversely reduce the dosage in the periods when there is less hydrogen sulfide.

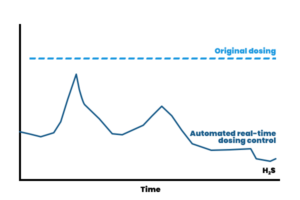

Automated real-time dosing control

Automated real-time dosing: The dosing follows sulfide levels in real-time.

To achieve even better dosing efficiency, the next step would be fully automated dosing control in real-time.

This dosing strategy is possible e.g., in an end-of-pipe dosing setup. In this setup, a sensor measures in the inlet to the discharge well, while a chemical feed pump doses chemicals directly into the discharge well. Here, we achieve direct real-time dosing, where the dosing system automatically adjusts the chemical dosing rate in a direct proportion to the sensor’s continuous measurements.

This strategy is not quite as easy to get started with as the two manual dosing strategies. However, if it is possible to set up the sensor measurements and the dosing station in the same place, it is possible to achieve the most cost-effective use of chemicals for hydrogen sulfide control with automated real-time dosing control.

Conclusion

This insight story shows how it is possible to get started with a smart dosing strategy for hydrogen sulfide mitigation. Do you want to hear more about how to get started? Check out webinar no. 5 in our webinar series to learn more.